Large Telescope Manufacturing Process

Type: Master’s Research Project

Year: 2014-2015

Key Skills: Mechatronic System Design; Matlab; C#; Micro-controller; Solidworks; Instrumentation; Control Theory; Thermodynamics; Manufacturing Process Development

Objectives:

- To investigate and design a noval process of manufacturing large telescope mirrors.

Summary:

As my Master’s degree research project, I worked on this solely by myself under the joint supervision of the company sponsoring the project and my professor.

- Researched the current methods and procedures of manufacturing large telescope mirrors.

- Studied the behaviour and properties of various different glass and high temperature material.

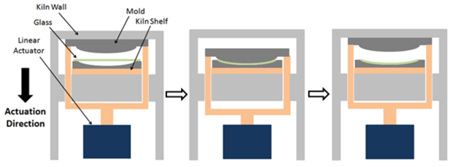

- Conducted experiments with a theoretical manufacturing process called slumping. In this process, a thin sheet of glass is supported by the edge and placed within a furnace. The furnace is held at the annealing temperature of the glass for a certain duration to allow the glass to deform due to its own weight. The system is then cooled down slowly back to room temperature.

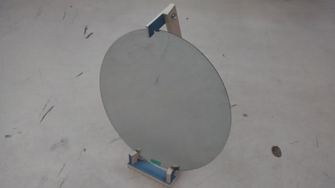

- Conducted various slumping experiments. Measured the test pieces using a laser measurement device and processed the data using Matlab.

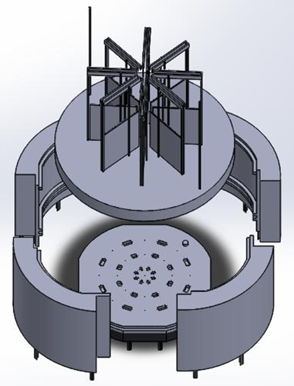

- Designed a large furnace capable of slumping glass up to eight meters with localized heating capability. Developed a method of measuring the surface of the glass during the process. The method uses lasers and relies on the reflection of the glass to determine the slope of the surface.

- Modelled all components using SolidWorks.

- Specified the components required based on heat transfer calculation, components limitation, strength calculation, and the designed measurement method.

- Presented the design for the circuitry and outlined a theoretical method of controlling the system. • Proposed an alternative manufacturing procedures based on test results and updated requirements. Created a general concept of how the new system would be constructed.