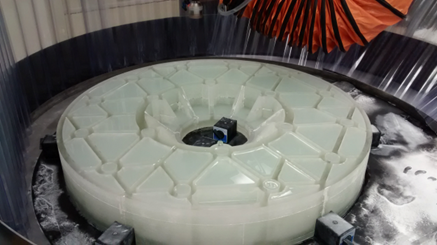

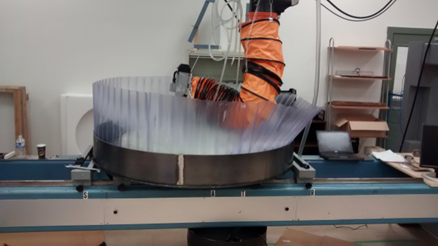

Robotic Mirror Grinding and Polishing Machine

Type: Industry Project

Year: 2014-2015

Key Skills: C++; Matlab; Robotics; Instrumentation; Manufacturing Process Development

Objectives:

- To develop a new method of manufacturing large telescope mirror through the use of industrial robots.

- To achieve submillimetric profile accuracy.

Summary:

This was a side project conducted in conjunction to working on my Master’s project. The company wished to confirm the feasibility and develop the capability of using an industrial robotic arm to grind and polish large telescope mirrors.

- The system primarily consists of a Kuka robot arm, a spindle, and a VFD for the spindle.

- Researched the current methods and procedures on glass grinding and polishing.

- Identified and specified the additional components required such as the VFD, diamond cutting tools, polishing pads, etc. Communicated with suppliers to learn about potential alternatives.

- Modelled and created the drawings of several adapters and tools using SolidWorks.

- Constructed and assembled the mechanical system and the electrical system.

- Programmed the Kuka robot and generated the desired tool path using Matlab.

- Designed and conducted tests to determine the performance of the system.

- Designed and constructed a simplified coordinate-measuring machine using the robot arm to measure the accuracy of the generated surface.