OmKnee Project - Semi-Automated Bone Sculpting Device

Type: MECH 458 (Mechatronics Design Project) Project

Year: 2012-2013

Teammates: Iftikhar Azam, Banda Logawa, Masashi Karasawa

Key Skills: Mechatronic System Design; Arduino; Solidworks; Instrumentation; Prototyping

Additional Information: Demonstration Video

Objectives:

- To construct a device that will assist surgeons in performing high accuracy and precision uni-compartmental knee arthroplasty. A virtual 3D curvilinear surface can be programmed into the device which will determine the areas where the bones can be drilled and create the virtual boundary to protect healthy tissues.

Summary:

Worked with three other classmates, tasks were assigned to individual member for accountability and equal workloads distributed between all members. This project later became the topic of Masashi Karasawa’s Master’s thesis project.

- Researched and studied similar devices and the current knee replacement procedures.

- Consulted with orthopaedic surgeons to identify user needs.

- Observed several knee replacement and hip replacement surgeries to understand the current procedures and identify the potential challenges.

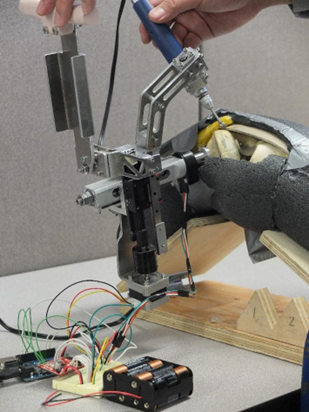

- Designed and manufactured the kinematic mechanism. The final design is a remote centre of motion mechanism where the orientation of the tool would not affect its position. The mechanism consists of a rotational joint and two linear joint for tool movement.

- Generated various concepts to achieve the desired functionality and ergonomics requirements.

- Tested the concepts using Lego prototypes and a fake knee model.

- Analyzed the structure through hand calculation and SolidWorks’ built-in FEA simulation.

- Created models and drawings using SolidWorks for various components.

- Machined and assembled the structure and mechanical components of the device.

- Designed, assembled, and programmed the electrical and control system. The final design includes an Arduino micro-controller, a prototype circuit board, a rotary encoder, a linear encoder, and a linear actuator.

- Designed and assembled the circuitry.

- Specified and purchased linear stage, rotary encoder, and linear encoder based on the required resolution and reaction time.

- Programmed the Arduino micro-controller to read and process the position information from the rotary and linear encoder. The micro-controller then commands the linear actuator to move the hard-stop to the programmed position, creating the virtual boundary.

- Prepared experiments to test and quantify the performance of the device.